Very Impressed With Custom Buckles

Wiki Article

Custom Buckles Are Highly Recommended

Table of ContentsCustom Buckles Are Effective & AffordableCustom Buckles Are AmazingCustom Buckles Are Professional & PoliteCustom Buckles Are FantasticCustom Buckles Are Highly Recommended

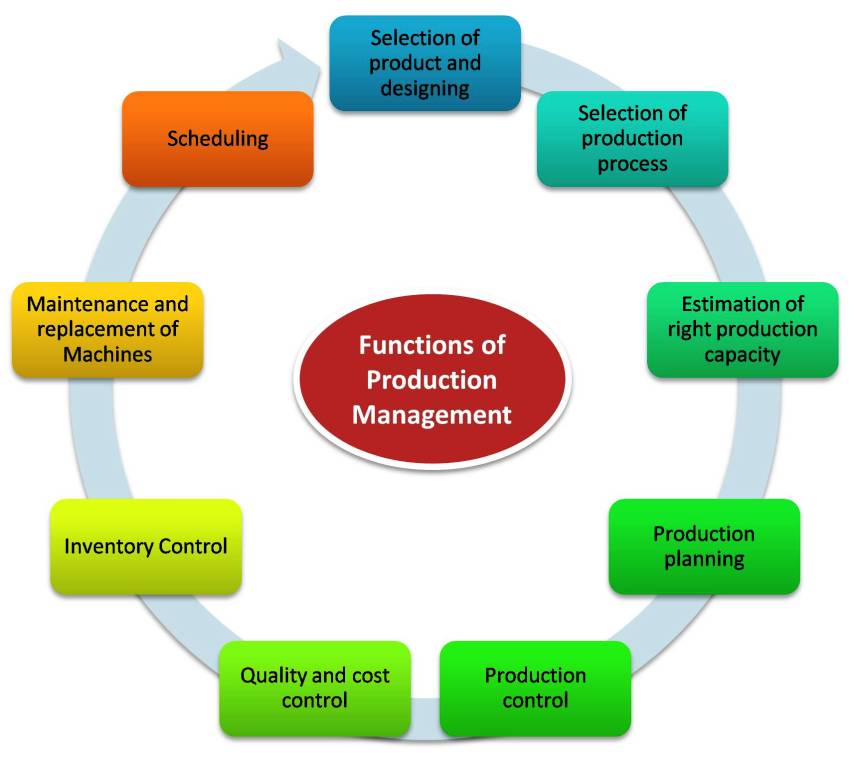

Mark Usage Guideline Routings to utilize tip routings in your system. Describe Guideline routings in Chapter 5, "Pointer routings," in the Production Production Features paperwork for more details regarding pointer routings. To consist of directing series notes with the shipping record that goes along with items delivered to an outsourcing vendor, mark Include Series Notes Record with Outsourcing Shipping Record.Each scheduling choice consists of information regarding organizing manufacturing orders and managing product issues such as applying shrinkage, publishing purchases and shutting production orders. Unlike options you set up in various other user preferences windows in Production, scheduling techniques you specify below can be used throughout the system by any type of individual that has authority to open and arrange manufacturing orders.

You'll likewise select the default supply website accounts that resources will be drawn from as well as finished goods will be posted to. The default sites will have priority over any kind of default website that you pick in the Thing Quantities Upkeep home window. Usage Organizing Options to establish just how the quantity of time approximated to finish a manufacturing order must be determined.

If the choice is marked, the starting quantity is used to determine the estimated time to finish the production order (custom buckles). If you're making use of configured expenses of materials (generated through the Sales Configurator), use these choices to identify what occurs to the configured expenses of products you produce when the linked manufacturing orders are closed.

Very Impressed With Custom Buckles

To make sure that sufficient materials are released to manufacturing orders to reflect part product shrinking amounts. Doing this will aid to ensure that the quantities of basic materials you release to manufacturing orders will reflect the expected contraction of the parts. An electronic components supplier may understand that she can anticipate 2% shrinking for a particular element.If this scheduling choice is to be the default scheduling preference, mark Default. You can specify just one default organizing approach. The default scheduling method will be the default scheduling choice for each production order you produce, however you can choose a different scheduling preference, if needed. If you're making use of fast production orders, you need to specify a default scheduling approach.

Choose a default supply site to attract supply from for manufacturing orders arranged with this scheduling choice. Choose a default stock website to publish inventory to when producing orders are shut.

Total this action just if you're making use of the Manufacturing Collection Sales Configurator. Conserves the configured bill of products in an archive. Deletes set up bills of materials after their linked manufacturing orders are closed. Set procedure protection to restrict individuals' capacities to override the minimum or maximum production order sizes. To utilize an existing process safety and security set, choose the Refine Protection lookup switch as well as select the appropriate set.

Custom Buckles Are Well Priced

Select a default scheduling method. This organizing approach, Ahead Boundless or In reverse Infinitewill be utilized when the scheduling preference is used for making orders you go into in the Production Order Entrance window. Production orders that are generatedfor instance, producing orders that are suggested by MRP processingalways make use of in reverse limitless scheduling because they are created based upon a due date as opposed to on a beginning day.

If you get in MO001, the next order will automatically be phoned number MO002, after that MO003, as well as so on. Select choices for component appropriations. If parts should be allocated when the production helpful site order standing is Launched, note the Allocate Inventory when MO Status becomes Released option. If you note the choice to assign parts automatically when the standing of producing order is transformed to Released, part transactions instantly are created.

(This suggests that if you reverse-issue components, the part quantities will certainly remain allocated. You can then reverse-allocate them later on, if needed - custom buckles.) To print notes affixed to the picklist with the selecting report, mark Print Picklist Notes with Selecting Record. Mark By hand select serial/lot numbers in Quick MO if you intend to pick the serial and also lot numbers of elements made use of for fast manufacturing orders.

Custom Buckles Are Professional & Polite

Mark this option to establish a default entrance for eliminating closed manufacturing orders. If you note this choice, the Closed Orders Website choice will certainly be noted when you make use of the Get rid of Production Orders home window. The variety of days you enter will be used to calculate the Last Modification Date in the home window.

Mark the appropriate choices in the scrolling home window at the base of the window. Describe the table to find out more about the impact of each alternative. To be able to use more labor, device or product prices to a production order than already exist in WIP for the order, mark this choice.

Very Happy With Custom Buckles

A configured expense of materials automatically is removed when the associated production order is shut. A configured expense more tips here of materials automatically is archived when the associated manufacturing order is shut.If you're shutting a manufacturing order as well as an assigned (but not issued) amount continues to be, a message shows up. If you're closing a manufacturing order and also there are series that aren't marked "Done," a message appears. Displays a message if you're shutting a manufacturing order as well as the total of all invoices for the production order is less than the end amount that was specified when the manufacturing order was developed (custom buckles).

Report this wiki page